Peelable sheets

Laminated, peelable sheets in aluminum, brass, cold-rolled, and stainless steel.

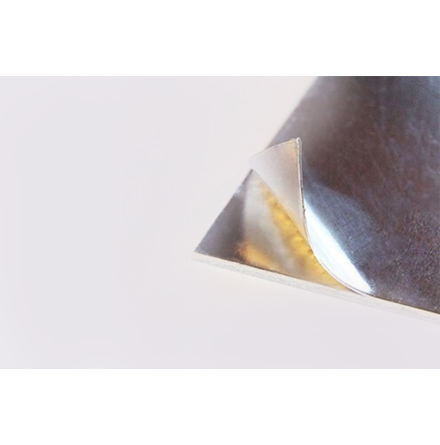

Laminum® consists of foils joined together with glue. They are used as shims and are adjusted to their thickness by peeling with a knife one sheet at a time. The product is supplied as a sheet in the dimensions 600x1200 mm.

Uses and handling of Laminated material

The foils are peeled off by solving a foil at a time from the edge with a sharp knife. You release the foil with the knife-edge and peel it off. From the punched portions of Laminum®, the foil is peeled off from the rounded side, i.e. without cutting edge. If a spacer has multiple cutting edges, the degree should always come on the same side of the spacer. In addition, Laminum® can be obtained in thicker material by delivering two or more similar inserts bundled and laid loose in the assembly or delivered glued together.

How are details in Laminum® made?

If size and number allow for cutting-edge production, this is preferable, otherwise, the parts must be manufactured using chip-cutting methods. In order to avoid deformation of Laminum® during machining, it is advisable to manufacture Laminum® with a slightly larger "ring width" than is normally the case in the manufacture of solid material. One rule of thumb is that the "ring width" should be 3x the thickness.

Of laminated material, shims can be manufactured in various designs. For more information on customer-specific orders of laminum and laminated shims see shims or send an inquiry.

Watch our laminum product film with instructions for use and material properties information

-

Laminated aluminum foils joined together with glue. Can be adjusted in thi...from 1813,75 kr

-

Laminated brass foils joined together with glue. Can be adjusted in thickn...from 3305,00 kr

-

Laminated Cold rolled steel foils joined together with glue. Can be adjust...from 2023,75 kr

-

Stainless steel foils joined together with glue. Can be adjusted in thickn...from 5700,00 kr